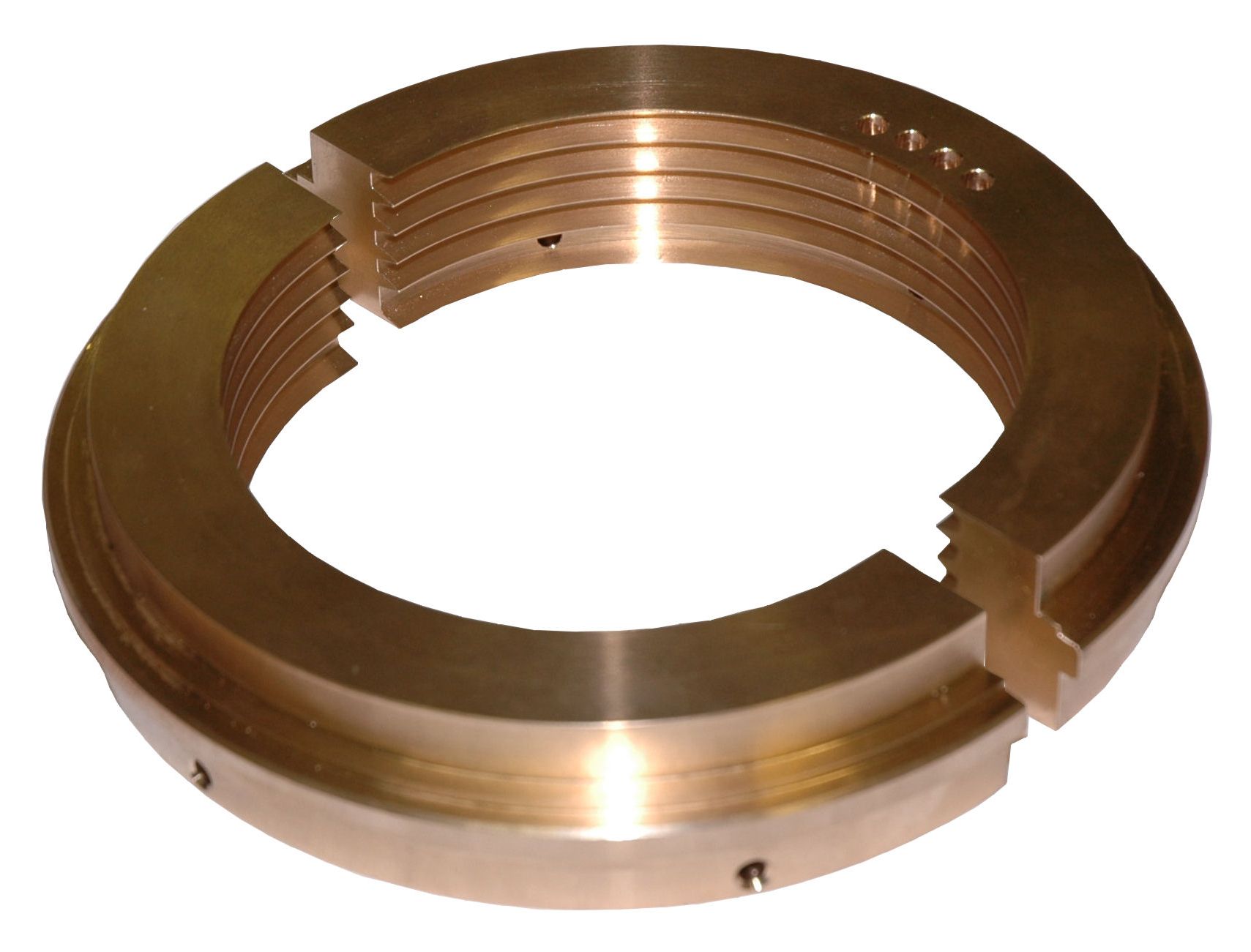

Producing parts cost effectively and to customer's lead times with OEM equivalent guarantees provided

Incorporating material enhancements and / or design improvements where possible

In house CAD capabilities to produce drawings, removing the restriction to the original manufacturer in the future

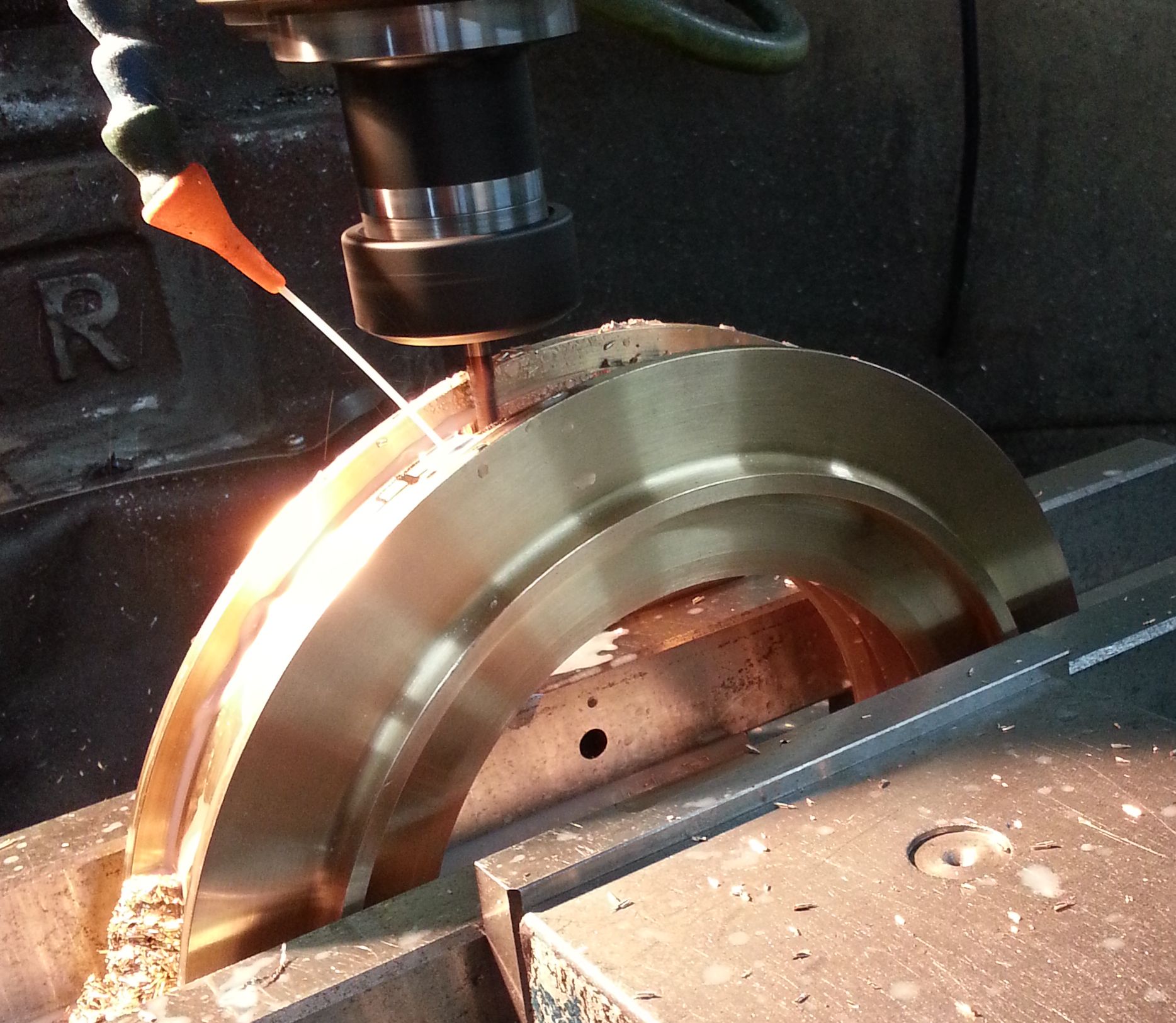

TMS are able to provide breakdown response times for components to fit with customer programmes by utilising our workshop facilities, specialist partners and network of approved suppliers

No minimum order restrictions we are able to provide our customers with comfort when looking for an alternative to the OEM

To minimise down time, TMS can hold exchange units that are swapped out in the field and refurbished between outages

BLADE SUPPLY

TMS are able to scan, produce and fit blades, shrouding, pins, spacers and closing mechanisms on a breakdown basis

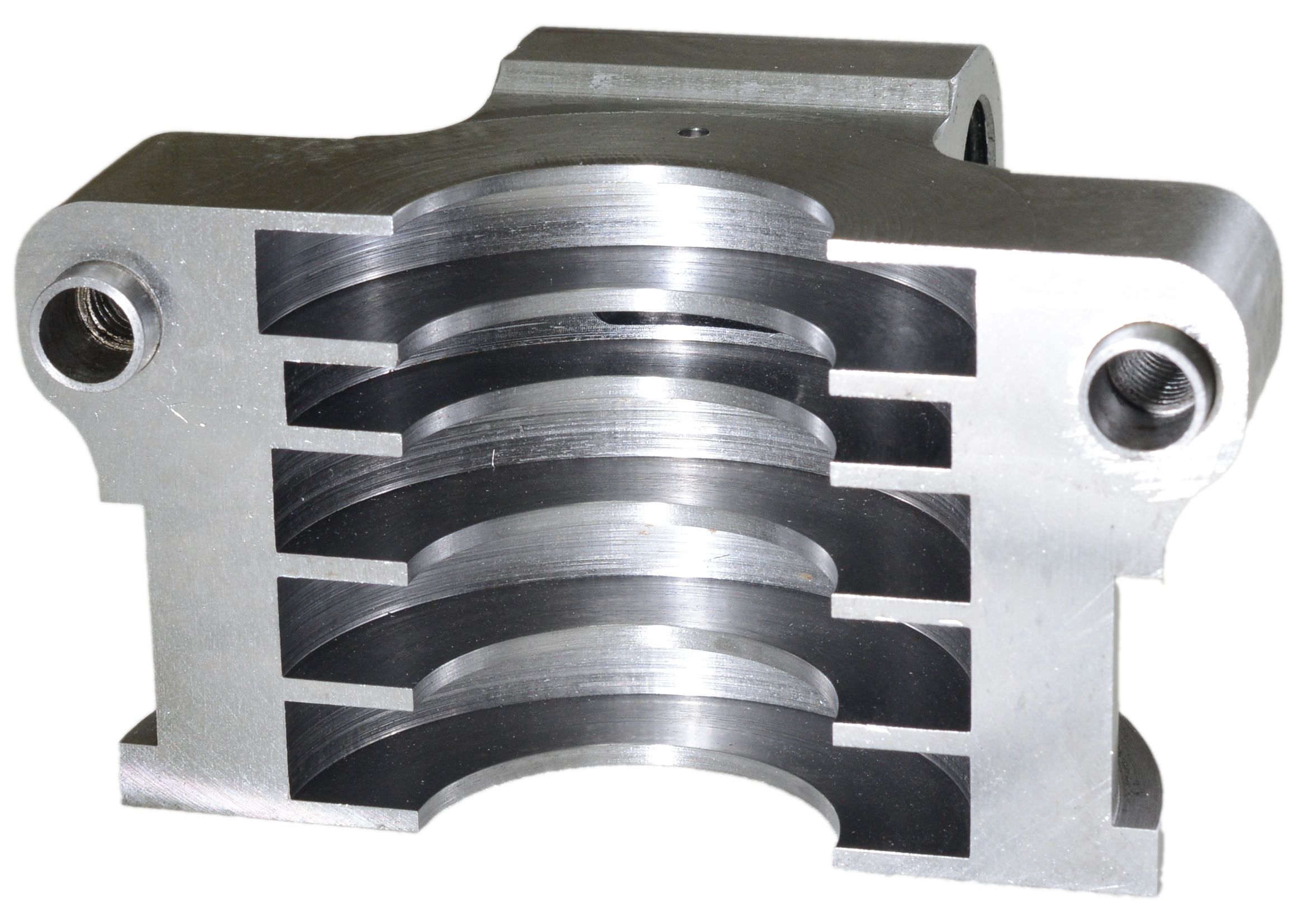

Part data capture

Components can be data captured, even when in worn condition, utilising laser scanning, portable CMM technologies and material analysis equipment and providing upgrades where possible

stock management

By taking care of your stock we can ensure that components are always ready and available when needed and preserved and maintained when they aren't